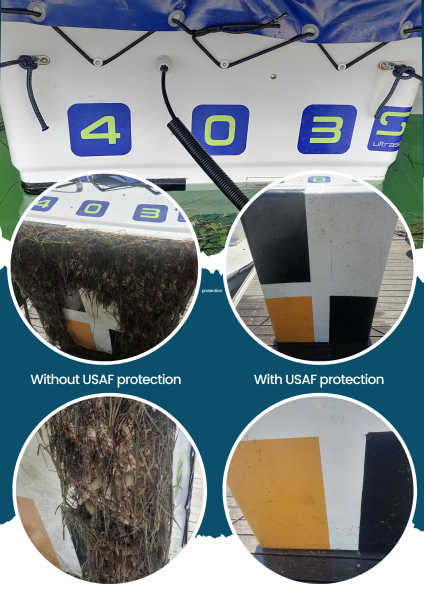

This summer we decided to test our products in particularly difficult conditions. We set them up in Piran for two months. You can see in the pictures below that our product passed the test with 4 AF coatings. Next report will be updated on the end off october 2022.

HOW IT WORKS

This disruption is created by the use of transducers that are attached to the interior of the hull. A control unit that creates specific low-powered ultrasonic waves operates the transducers. The hull transfers these vibrations to the water where it creates acoustic cavitation, which creates acoustic pressures low enough to cause the vaporization of the water right along the surface of the hull. These vapor bubbles then burst, creating an incredible hyper-localized pressure differential. This pressure differential generates strong water movement on the microscopic level, but it also creates a difficult environment for microorganisms to attach themselves to the hull due to the strong micro-currents created by acoustic cavitation.

While ultrasonic antifouling systems work great with many boats, they won’t work with wooden or cored hulls. This is because the foam or wood dampens the ultrasonic wavelength making it ineffective at vibrating the exterior hull. Steel and solid FRP hulls offer the best transfer of ultrasonic waves, amplifying them like a soundboard and allowing each transducer to protect a large area.

While these systems are unique and offer great protection against fouling, they are best utilized in conjunction with bottom paint, soft or hard. Most manufacturers, however, suggest using them in combination with a hard antifouling paint.